Infrastructure

Addressing Infrastructure Gaps to Build the Biomanufacturing Industry

The United States faces a foundational gap in domestic pilot- and intermediate-scale bioindustrial manufacturing infrastructure. As a result, American companies must seek relevant facilities overseas to scale-up their biomanufacturing processes for innovative products from the laboratory to commercial production.

To address this gap and realize the promise of bioindustrial manufacturing, Congress provided a down payment in 2023 for a strategic, multi-year effort to catalyze the creation of pilot-scale infrastructure through BioMADE. These investments will transform American manufacturing, bring back manufacturing jobs, retain American R&D efforts, create well-paying jobs, and preserve U.S. leadership in the 21st century bioeconomy.

In 2025, BioMADE announced a demonstration-scale facility in Minnesota, and two pilot-scale facilities in California and in Iowa. BioMADE is also exploring opportunities in Georgia, Hawaii, Indiana, and North Carolina to establish bioindustrial manufacturing facilities there.

Photo above © North Carolina State University

Demonstration-Scale Facility in Minnesota

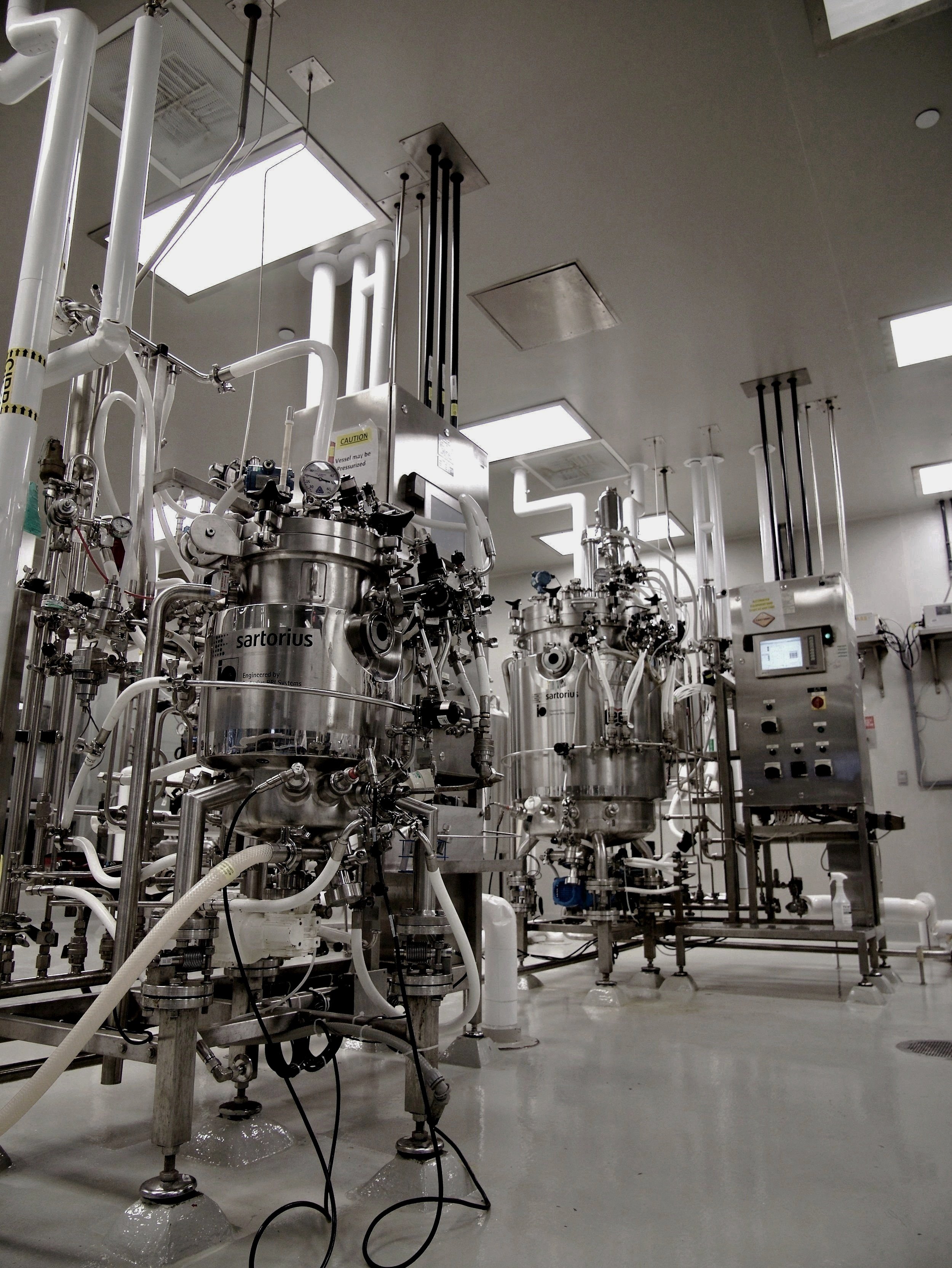

BioMADE will operate a 122,000 square foot demonstration-scale facility in Maple Grove, MN that will feature two 25,000-liter industrial fermenters, allowing innovative companies of all sizes to take their processes to the next level as they march toward full-scale commercial manufacturing.

Demonstration-scale facilities represent a critical step to move products out of the lab and into the defense and commercial market. BioMADE’s Maple Grove facility will have a special focus on chemicals and materials, offering the advanced security and safety capabilities, including the ability to process volatile liquids.

The multi-user facility will include downstream processing equipment such as a centrifuge, membrane filtration skid, ion exchange columns, crystallizer, and drying, which can produce both liquid and solid final products. Lab capabilities to support demonstration-scale manufacturing will include analytical testing capabilities and process development laboratories.

The facility will also include on-site education and workforce development opportunities, with hands-on laboratory training as well as potential for training on relevant equipment and procedures for incumbent workers or students. Learn more here.

© Iowa State University

Pilot-Scale Facility in Iowa

BioMADE will operate a 15,000 square foot pilot-scale facility near Ames, IA that will include up to 10,000-liter industrial fermenters, dry and wet lab space, and downstream processing capabilities centered around the development of agricultural bioproducts, chemicals, food and more.

BioMADE's facility will complement other Iowa-based facilities to increase the speed at which companies can move through technological development and scale-up processes, bringing innovative biotechnologies from the laboratory bench to commercial production.

As a multi-user facility, the Iowa site will serve companies around the country as they seek to move biomanufactured products into the market. Learn more here.

Pilot-Scale Facility in California

BioMADE will operate a 25,000 square foot pilot-scale facility in Hayward, CA that will feature multiple aerated stirred tanks with volumes of up to 4,000 liters along with downstream processing capabilities including harvest tanks, centrifuges, membrane filtration, evaporation, and spray drying. It will also have the ability to bring in third party equipment skids for additional downstream processing operations.

The facility will focus on a broad range of products – including chemicals, materials, and food – to serve a variety of innovative biotechnology companies in the San Francisco Bay Area and beyond.

As a multi-user facility, the Hayward site will serve companies across a wide range of applications, from small-scale development capabilities to commercial testing and process refinement.

Pilot-scale facilities represent a critical step to move products out of the lab and into the defense and commercial market. Learn more here.

© Amyris

The Vision

BioMADE launched its plan for a network of 12-15 pilot-scale bioindustrial manufacturing facilities around the United States in 2023. With federal and state co-investments, the BioMADE Pilot Plant Network (PPN) will grow to include pilot facilities throughout the U.S. that provide an essential service to growing bioindustrial manufacturing businesses.

Sites in the network will take many forms and have unique capabilities based on demand, feedstock availability, defense needs, and proximity of existing facilities and workforce training centers. BioMADE will establish the network in phases to best meet the needs of the industry as it evolves, and to take advantage of lessons learned through the development of the network.

These pilot-scale facilities will be made available to companies needing piloting and process development capabilities as they look to build a commercial scale manufacturing facility.

© Capra Biosciences

About the Sites

These bioindustrial manufacturing sites will:

Foster innovation by de-risking new technologies and products with innovative start-ups, small companies, and large industries alike

Build far-reaching career pathways and create additional jobs through the construction and operation of facilities

Support American farmers and create new markets for their feedstocks

Build and strengthen domestic supply chains for materials that go into everyday products used by Americans

Improve environmental sustainability and reduce reliance on foreign inputs